Who We Are

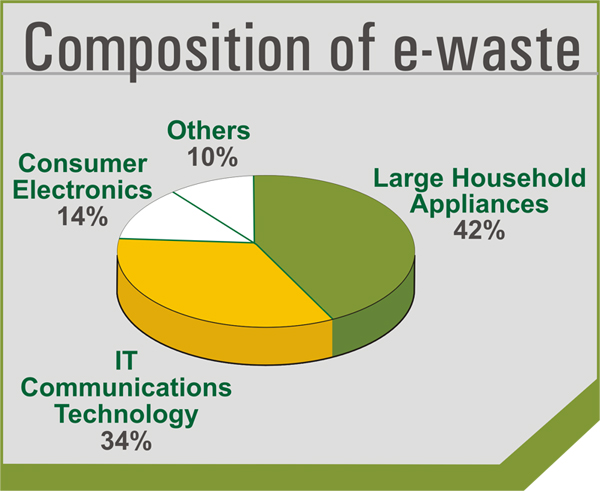

Electronic waste, e-waste, e-scrap, or waste electrical and electronic equipment (WEEE) describes discarded electrical or electronic devices. "Electronic waste" may also be defined as discarded computers, office electronic equipment, entertainment device electronics, mobile phones, television sets and refrigerators.

This definition includes used electronics which are destined for reuse, resale, salvage, recycling, or disposal. Green businesses are the key drivers of the economy in the current global business scenario. Of the various green initiatives, waste recycling creates the highest positive impact on the environment. Of all the different types of waste, electronic waste has the characteristics of:

- The fastest growing segment of waste

- Most valuable due to its basic composition

- Very hazardous if not handled carefully.

What We Do

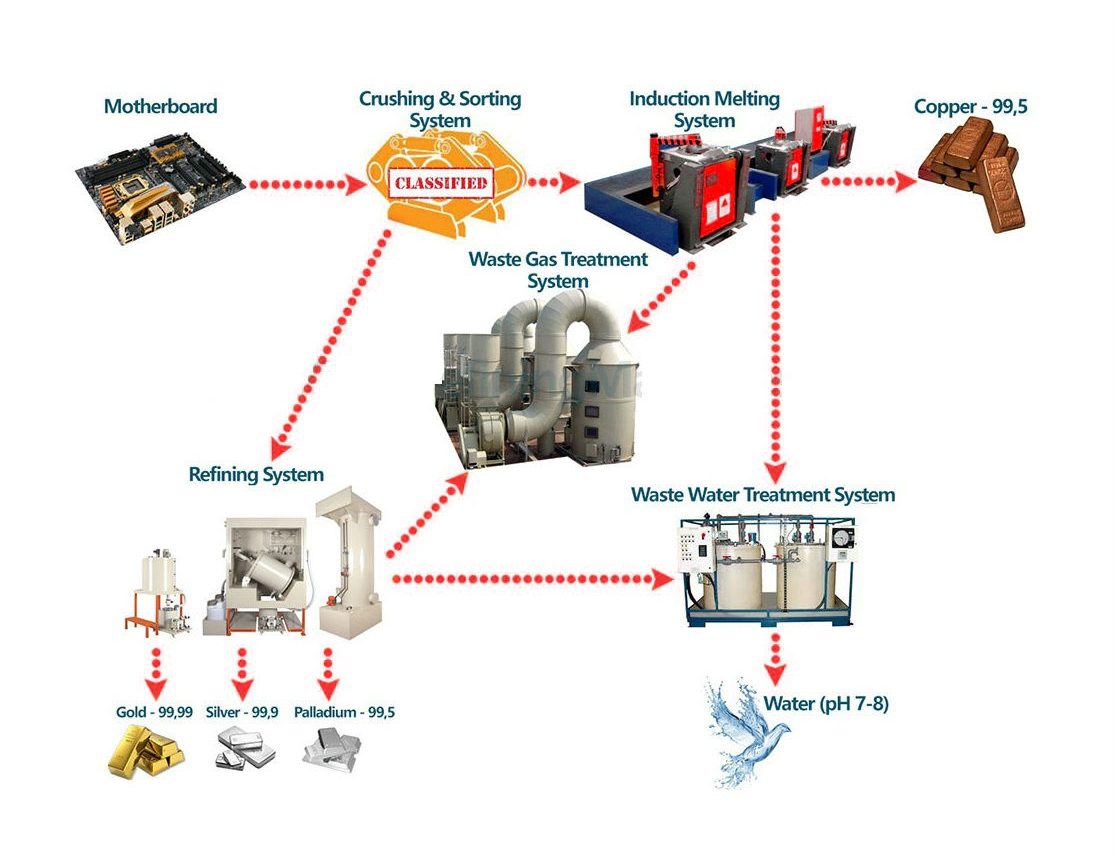

However, the sector is very new with only a few corporate players in India and globally. Most of the electronic waste management sector is currently handled by the unorganized/informal sector in India. However due to lack of skills, knowledge, awareness, etc., the sector has remained highly labour intensive, environmentally unfriendly and unhealthy. If done in the right way, and in an organized fashion, e-waste management can become a dominant economic sector. The e-waste business is highly profitable from the economic as well as environmental perspective. Automated or semi-automated large capacity plants require less labour, can consistently work at high efficiency and produce a much better quality of the final product. Therefore, they are extremely cost effective in the long run. Thus, even if there is competition of the unorganized sector, e-waste management can be an economically viable and a high returns business for the organized industry.

.